bic_bicknell

2012-05-06 07:09:00 UTC

TLS_Russ

2012-05-06 07:35:00 UTC

next clean up the clutch plates,you must get rid of all the dodgy oil, a good blast both sides with brake cleaner, frictions and steels,let them dry then soak the frictions for an hour or two in your GOOD oil,

put it back together and hopefully that will be problem solved

bic_bicknell

2012-05-06 07:49:00 UTC

http://www.putoline.com/en/products/cat ... c-4-10w40/

TLS_Russ

2012-05-06 08:01:00 UTC

I would still suspect the oil, it may not even be whats on the invoice in the engine!

As soon as I read your first post on this I thought.... OIL.....

I have had similar problems with the TLs which has a slipper type clutch, dealer service, Mobil full synthetic, clutch slip...... strip the clutch, clean off the dodgy oil... flush the motor with fresh Motul 5100 oil problem solved

bic_bicknell

2012-05-06 09:11:00 UTC

http://www.suterclutch.com/downloads/SR ... chr_V2.PDF

Interesting thing is that they say that clutch might slip due to increase in power over standard engine and my bike has gone from 118BHP to nearly 127BHP over the last three years. They say to just go up in spring strength to compensate for this so I will try this as well. But they also say check the oil too.

KTM666

2012-05-06 10:06:00 UTC

kevxtx

2012-05-06 10:41:00 UTC

If the clutch pack is in good condition & within the Suter measurement spec & you have changed the oil & the clutch jet is clean, go 400n or 600n up on the pressure plate diaphram (Link Below), I run one up from standard on my SMT slipper & have never had any problems with slip & I have around the same HP as you. http://suterclutch.com/forge/shop.cgi?c ... ategory=73

drswade

2012-05-06 15:07:00 UTC

Mine was worn and slipped like crazy with little warning before it got there.

The tolerance for the wear is almost non existent it is so minimal.

I will search for old threads I posted on this.

Perhaps some of you who purchased one of my clutches has sorted this problem by now?

drswade

2012-05-06 15:11:00 UTC

Found the post:

viewtopic.php?f=1&t=14035&p=161957#p161957

bic_bicknell

2012-05-06 18:11:00 UTC

bic_bicknell

2012-05-06 18:31:00 UTC

bic_bicknell

2012-05-06 21:05:00 UTC

There is also a small preassure ring at the very end of the whole clutch pack, if this one is missing you also run into problems.

Usually its missed becaused it sticks with the oil to the old clutch basket when you change over to the slipper clutch.

The installation manual of the Sutter clutch is also not too bad and in english, review all steps.

SDNerd

2012-05-06 22:03:00 UTC

SDNerd

2012-05-07 09:48:00 UTC

SDNerd

2012-05-07 16:00:00 UTC

Stated previously, and here again: The diaphram spring that comes with the Suter is inadequate. I have posted what does work in other threads.

And yes, like any spring, the diaphram spring can yield over time.

bic_bicknell

2012-05-07 16:45:00 UTC

Of course a spring will age over time and if the clutch disks are worn out its a good idea to change the springs also, but if its in good shape it works like it should.

SDNerd

2012-05-07 17:39:00 UTC

Post missing.

Davo-Singapore

2012-05-08 05:50:00 UTC

Mine is actually a used battle one and nobody had a problem with the clutch itself. The issue which came up using it on the race track

every weekend was that the friction discs show massive wear. This came up unexpected quick and lots of drivers sold the Sutter and

went back the OEM clutch. What i'm saying here is that the clutch itself has no embedded problem in construction, but to make

it work like it should proper assembly and overall thickness of the clutch package is key. The way the clutch work depends

on this parameters. If you are looking for a simpler much more tollerant slipper clutch look for the TSS Clutch. It will not

work as smooth as the Sutter but is a lot more tolerant on outside parameters.

SDNerd

2012-05-08 16:02:00 UTC

Post missing.

bic_bicknell

2012-05-08 19:10:00 UTC

fuel

2012-05-08 19:47:00 UTC

Post missing.

bic_bicknell

2012-05-09 07:13:00 UTC

SDNerd

2012-05-09 16:09:00 UTC

bic_bicknell

2012-05-10 15:20:00 UTC

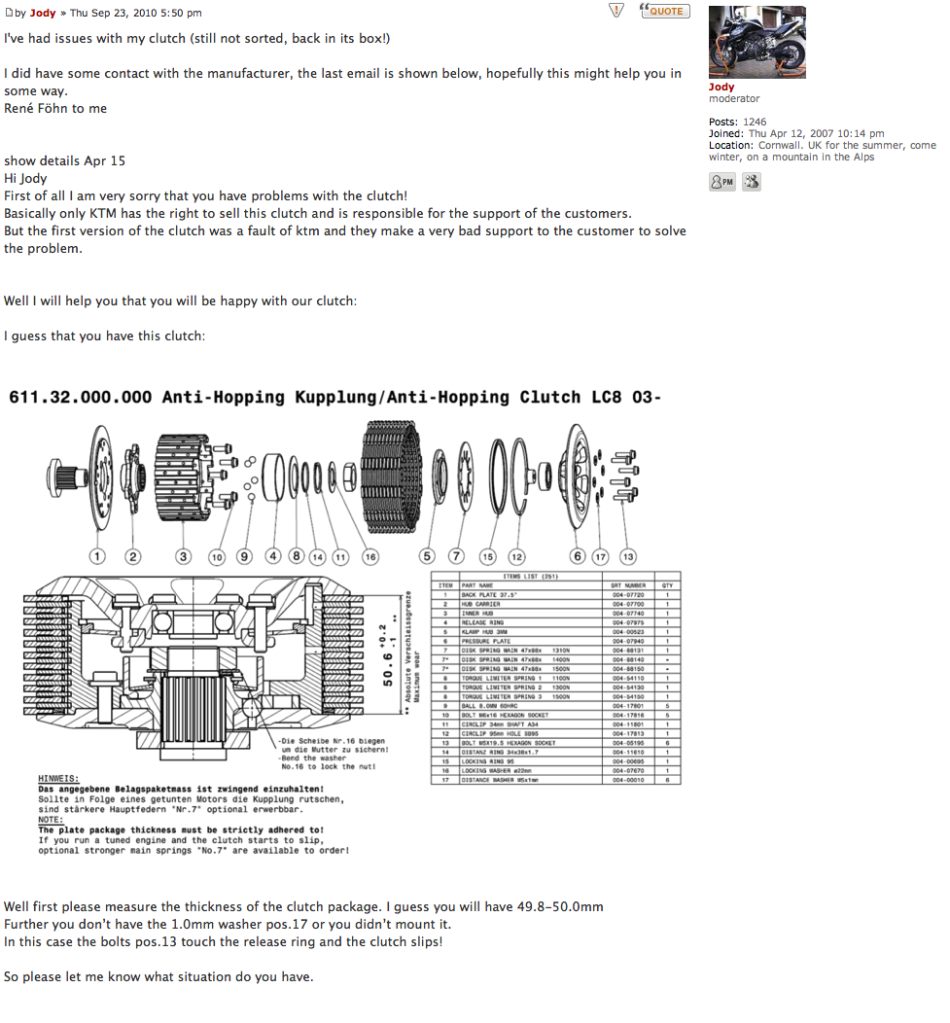

See below:

Hi David

Normally I should send you to the KTM dealer you bought the clutch from, but I understand that not all of them really know how a slipper clutch works.

What does your pressure and your back plate look like? Any wear on them?

Please measure the gap between the Bolt, position 13 and the release ring position 4, it should be aprox. 1.2 - 1.4mm.

Measure it like this, disassemble 1 of the 6 Bolt, and then measure the depth from the surface to the release ring, minus the bolt length.

If this is OK, no gambling is necessary with shims!

Please check and let me know.

Freundliche Grüsse / Kind regards

Roger Sutter

Masch. Ing. HTL

Production and Procurement

Suter Racing Technology AG

Mettlenstrasse 3

8488 Turbenthal

Tel: +41 (0)52 397 10 72

Fax: +41 (0)52 397 10 70

www.suterracing.ch

www.suterclutch.com

Davo-Singapore

2012-05-12 01:34:00 UTC

Post missing.

omky756

2012-05-12 02:34:00 UTC

Post missing.

omky756

2012-05-12 02:53:00 UTC

drswade

2012-05-12 13:33:00 UTC

IT was smooth and seemed pretty close to the stock pull, which IMO is pretty stout anyway.

The Yoyo was jerky and not nearly as smooth.

I ran the piss out of both clutches and the Yoyo still looked new when I sold it here.

The Suters....not so much.

bic_bicknell

2012-05-12 15:59:00 UTC

Took off the six M5 bolts and had a look at the ends. Really obvious that they have been rubbing against the ring as mentioned in the e mail from Suter to Jody. So I put six 1mm washers on them and reinstalled. Was going to measure all the plates but thought it easier just to see if this has done the trick. If it is I'm a bit perplexed because I've been running this clutch for two years or more with no problem 'till a month or so ago. Why it should suddenly start doing this is a mystery to me. But if the washers are the answer I might take them out again and turn down Imm off the ends of the bolts - seems a better way of doing things than adding in a washer.

BASH69

2012-05-12 21:18:00 UTC

Can you throw up the installation instructions for us to have a look at Bic? That may help as i have no idea what the Suter looks like?

roamer

2012-05-12 23:24:00 UTC

bic_bicknell

2012-05-13 17:20:00 UTC

So I strip the clutch again when I get home. The six bolts are STILL rubbing on the ring underneath the main spring - I can see where they have worn another new groove/polished line at a different angle from the first ones shown in the pictures. This is even with the 1mm washers. So I think I better measure the clutch pack to see if these are all in spec. They are all fine and as follows:

Total clutch pack is 50.77mm

Metal plates are all between 1.93 and 1.95mm

Friction plates are brand new and all 2.74mm

It's the total clutch pack that matters and it shouldn't fall below 50mm

I'm going to email back to my friend at Suter tomorrow and ask him what he advises. Me - I'm tempted to turn down about 2mm off the end of each bolt. Even from the cross section drawing you can see that there is quite a lot more bolt protruding beyond the bottom of the plate they screw into. It's obvious from looking at the the way the clutch works that if these bolts even come into contact at all with the ring that is attached to the basket then the main spring will not be able to push the plates together fully - no matter how strong the spring is. They would effectively stop the travel of the outer pressure plate.

I'm hypothesising that by adding the washer I've lessened the problem but need to be more radical. I don't really want to add two washers - doesn't seem like a good idea and the heads of the allen bolts will maybe start to touch the inside of the clutch cover.

Lets see what Suter says.

One other thing I've learned. DON'T try to take the clutch apart with a hot engine. The six M4 bolts are much tighter and almost impossible to undo. I've more or less ruined on allen head and mashed up two keys. When the engine was cold again it was much easier to undo the rest. I will get a torque setting from Suter. I'm going to fit new bolts when I reassemble.

SDNerd

2012-05-13 17:47:00 UTC

Post missing.

bic_bicknell

2012-05-13 20:39:00 UTC

I just want to be able to get all that new found power/torque at the top end that my motor has got. Need the total package of full exhaust system, RC8 trumpets and quick-shifter working seamlessly to have the run up the start finish straight at Brands to fend off the inlne fours! It's funny really, riding smoothly about and sensibly on public roads you'd never know the clutch was slipping. It's only when you really, really ride hard and aggressive that it happens. But on a track it would be really obvious immediately and piss me off big time. Plus, I can't stand to know that something is not working perfectly - it bloody should do given the cost of it!

bic_bicknell

2012-05-14 07:22:00 UTC

I haven't heard back if you checked those ...

Colonel_Klinck

2012-05-14 11:24:00 UTC

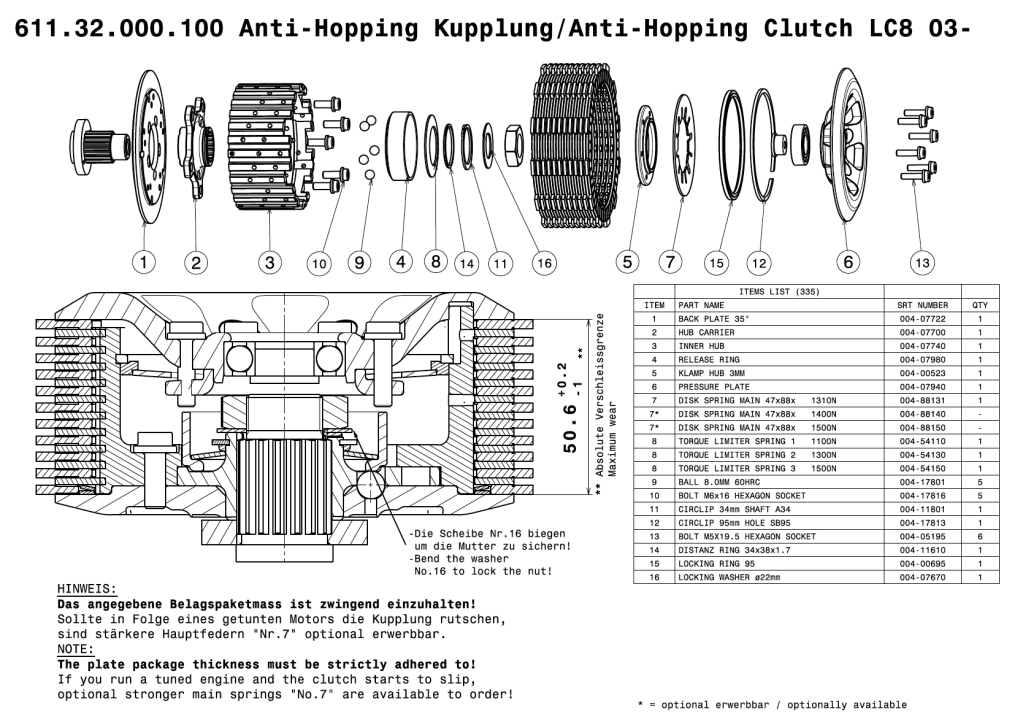

Hi David

Bolts should definitely be replaced, all spare parts are available separately, please check attached drawing.

The bolts are not too long. Everything should be fine and working as you describe!

Clutch Plate package is fine with this thickness as well.

The only route of the problems I see could be the engine oil or the main spring.

Did you always use the recommended Motorcycle engine oil?

This is often the reason for slipping clutches!

Don’t think you are doing something good in using the fully synthetic, bloody expensive ones, just use what is recommended.

What is written on the main spring, 1310N? We could go to a 1500N one!

Please let me know.

It's all right him saying that everything should work fine but it obviously doesn't and the bolts are too long. I've ordered some new bolts - 16mm long, (not from Suter) and am going to try with these.

If the clutch still slips I will consider going up a strength of main spring but as already stated they are not cheap.

Klink....can you see from the drawing that the washer under the main nut is indeed the locking/tab washer that we both have. It's not a KTM part but a Suter one.

SDNerd

2012-05-14 12:34:00 UTC

Colonel_Klinck

2012-05-14 16:25:00 UTC

bic_bicknell

2012-05-14 20:22:00 UTC

Bic have your spare set on standby please

Colonel_Klinck

2012-05-15 15:18:00 UTC

I've asked the Suter guy to came back again with a place to buy the parts from. I'm going to get a new washer or two and a set of the six M5 bolts. But in the meantime I have found this official Suter site with the main springs for sale at less price than previously posted. (78 Swiss Francs is about £51). Need to check the diameter of our spring - not sure which one it is - hope not the 86mm because the range for this is limited. This site doesn't list the washers and bolts as parts.

http://suterclutch.com/forge/shop.cgi?c ... ategory=73

bic_bicknell

2012-05-15 15:45:00 UTC

Post missing.

omky756

2012-05-15 19:31:00 UTC

On this thread there has been a lot of talk about the six M5 bolts that are maybe too long and hitting another component in the clutch causing it to slip. I've tried shimming them with 1mm washers to no avail - they still show signs of contact with the ring component, (Part number 4). If you look at the cross sections of the clutch you will see that the bolts have a clearance of about 1.5 mm with this ring when the clutch is operative in normal use.

What the guy at Suter confirmed today is that the bolts DO COME INTO CONTACT WITH THE RELEASE RING. THEY ARE MEANT TO. This is when the anti-hopping mechanism is activated by the reverse torque mechanism. That is why they show wear to the ends - not because they are too long but because that is how the slipper clutch works. This is normal and expected signs of wear and contact. (I'm really surprised that this is the way it's engineered but it is true).

So..... if anyone has added a 1mm washer to the bolt when it was not meant to be there they have effectively eliminated the ability of the clutch to deliver the slipper ability. If I had gone ahead and turned down these bolts in the belief that it would cure slip then I was wrong. I would have just ended up with a normal clutch that was not a slipper - and it would still have slipped under power.

THESE BOLTS HAVE NOTHING TO DO WITH THE CLUTCH SLIP I AM EXPERIENCING.

He has given me the part number for new bolts and a new stronger main spring. He says that this is all is can be. Everything else that I have sent him regarding the clutch plate dimensions and total pack width he has confirmed is within tolerance.

So in the final analysis it looks like SDNerd is the winner here - it's all down to spring strength. The additional BHP and torque of my engine must be just too much for the spring I have fitted.

He also confirmed that the torque setting for the bolts is 5nms.

I still can't believe that this precision clutch is engineered to work with one component interfacing at different revs with the ends of six bolts that are actually there to hold on the pressure plate. It just seems bad engineering to me. If the bolts are torqued down differently they will all be a different lengths and the pressure ring will be touching them unevenly around the six contact points. If you have any engineering mind and can read the cross section you will appreciate what I am saying.

The only reason I can see them designing the clutch this way is that the bolts are made from some extra special material that performs well in friction situations and that when they wear down too much you can replace them easily and cost effectively. The Suter guy says they should be replaced. They do call them Suter 'special' bolts in some texts so I can imaging that if you use normal steel bolts as replacements then they might wear out really fast.

Anyway, I bet no one is reading this thread anymore and if you are you are all bored of the subject!!

I just want a fooking working clutch like I used to have.

SDNerd

2012-05-15 19:43:00 UTC

In as much extra work you're going through..

It is definitely a learning experience..

How many times now have you

pulled it all back down now.>??? Once is enough..two times ok..

For me..any more and my brain hurts...lol

Thanks..!!! I've yet to get mine together..

But I have a much better understanding without having to suffer

what you have...

This post has a LOT of info to share...

bic_bicknell

2012-05-15 20:12:00 UTC

Post missing.

bic_bicknell

2012-05-19 04:47:00 UTC

Out of interest I tried to find a UK distributor for Suter but the only one listed on their website is DRL Racing and they don't answer their phone and haven't rung back two days after leaving a message. Suter are really nice people, and make good products, but they are not set up to sell parts or deal with after sales service.

Tried another way too. Rang Jim Aim KTM and talked to a guy there. Asked if they sold Suter clutches but they don't - only Sigma ones. So I asked about the KTM Hardparts clutch and said that as far as I knew it was actually a Suter clutch with KTM branding on it. I sent through the drawings from Suter for them to compare to the microfishe files they have of the KTM hardparts clutch and they rang back to say that it was identical and that the parts are the same.

What is interesting is that the replacement main spring listed for a superduke is the same spring I have, (1235nm) but the same clutch for the RC8 is listed with a spring which is 1600nm. So they could easily order me the six bolts, the tab washer and the stronger spring. They are going to check on Monday what the price is and whether they have the option through KTM to order different spring strengths rather than limited to just those two. But anyway it might be quicker and easier than going through Suter.

Has anyone out there got an RC8 with a Hardparts slipper clutch? Or do they all come with one as standard? I want to know how hard the actuation on the lever is. I know that it's a different engine and everything and it doesn't mean that fitting this spring will feel the same on an SD but at least the clutch won't slip if it can cope with the RC8 power.

drswade

2012-05-19 13:54:00 UTC

It is exactly the same clutch just re-branded.

I covered this before I think.

Shame on a dealer for not knowing this. But what do you expect, right?

The thing I encountered was that Suter was under contract to not sell parts for the KTM clutch, rather you must buy from KTM.

I contacted KTM America, the headquarters, and they directed me to Suter as they couldn't get parts.

But Suter isn't allowed to sell parts.......circle jerk.

As much as I love KTM and would probably buy an RC8R if I bought another bike, the company itself is a classic example of having one's head up one's ass/arse.

SDNerd

2012-05-19 15:27:00 UTC

Post missing.

bic_bicknell

2012-05-19 18:33:00 UTC

If I can find a convenient way to order through a UK dealer then I will.

SDNerd. It's no good to me knowing how you get stuff in the States . I'm here in the UK mate. Anyway it sounds as though you're no better off than us anyway. I'm just trying all the options here. I've found a direct link with Suter but it's shit for purchasing stuff. Just want to find out a way that any future SD owners can short cut to the best way forward.

Anyway, why do you not think I'd be happy with the stronger spring - it's you that have been recommending that this it the answer to my slip!! Do you mean a 1600nm it's too strong? I'm trying to order a 1400nm - this is what I feel will be adequate.

Colonel_Klinck

2012-05-19 19:10:00 UTC

SDNerd

2012-05-19 22:40:00 UTC

Post missing.

stalker

2012-05-20 18:53:00 UTC

bic_bicknell

2012-05-22 05:33:00 UTC

Decided to take the plunge yesterday and pay Suter direct into their Swiss bank account for the parts. They sent me a new invoice with the correct numbers on it and then it took me over an hour on the internet to do an international bank transfer. Had to keep paying additional fees for the transfer and also accept any that their bank asked for, (even though they didn't say how much it would be!!). And it might take up to 4 days before they actually get the fubds and send the parts. What a faff.

Just hope that everything goes smoothly and they don't get held up in customs with even more charges to pay.

Still waiting for Jim Aim to get back to me about whether they can get parts and then I can post up comparison prices.

Also Suter UK distributor guy did ring me back on Saturday from a racetrack - could hardy hear what he was saying.

stalker

2012-05-22 06:49:00 UTC

bic_bicknell

2012-05-25 07:23:00 UTC

I'll fit them tomorrow and hope it solves everything.

omky756

2012-05-25 07:40:00 UTC

Post missing.

Colonel_Klinck

2012-05-25 10:49:00 UTC

bic_bicknell

2012-05-25 11:31:00 UTC

Thought there might be something up with the amount they were invoicing me - something didn't seem right.

So the package has only got one spring in. Really sorry mate, not sure how this has happened. Only good bit was that you don't actually have a slipping clutch do you?

But they have sent two lock/tab washers as I asked for.

I can post it over to you if that's the best way or you can drop in to work again - let me know what's best.

Colonel_Klinck

2012-05-25 11:45:00 UTC

Post missing.

bic_bicknell

2012-05-25 12:05:00 UTC

Colonel_Klinck

2012-05-25 13:01:00 UTC

Post missing.

bic_bicknell

2012-05-26 06:32:00 UTC

omky756

2012-05-26 06:39:00 UTC

Post missing.

Colonel_Klinck

2012-05-26 06:53:00 UTC

SDNerd

2012-05-26 13:30:00 UTC

Post missing.

Colonel_Klinck

2012-05-26 15:06:00 UTC

bic_bicknell

2012-05-26 15:18:00 UTC

This is the slipper ring that moves out when there's reverse torque applied through the clutch. This edge pushes against the bottoms of the six M5 bolts and releases the pressure holding the pack together.

Will test ride tomorrow. please, please, please be fixed with no slip under power.

Colonel_Klinck

2012-05-26 16:19:00 UTC

Colonel_Klinck

2012-05-26 20:20:00 UTC

Superdan

2012-05-26 21:27:00 UTC

CEREC1

2012-05-26 21:31:00 UTC

Post missing.

bic_bicknell

2012-05-26 22:10:00 UTC

I think that the standard clutch with the 1230nm spring is just not up to the SD when you liberate the extra power. Interesting that our bikes are the same really, Motobox, full akras, etc.

Colonel_Klinck

2012-05-26 23:12:00 UTC

SDNerd

2012-05-27 01:00:00 UTC

Post missing.

Colonel_Klinck

2012-05-27 04:57:00 UTC

Post missing.

Viking

2012-05-27 07:03:00 UTC

You'll get good money for it and for a little bit more you can have a brand new sigma.

Miles less hassle than all this carry on man and a lot easier to fine tune by just changing a £3 steel plate. Takes 5min.

Colonel_Klinck

2012-05-27 07:09:00 UTC

The only thing I did notice was that 2 of the steels were put in with the sharp edge from being punched out facing outside where as all the others had the sharp edge in. Can't imagine that was making it slip though. Measured the pack again and it was only 49.89mm so I need new friction plates and steels. Going to order those and the heavier spring this week. Bit gutted it didn't work though. I think I might also put the heaviest slipper spring in as well. Don't think I require that much slip tbh.

Colonel_Klinck

2012-05-27 07:19:00 UTC

Post missing.

Superdan

2012-05-27 07:56:00 UTC

Post missing.

Viking

2012-05-27 08:45:00 UTC

The GSXR plates are the same as the sd ones apart from you can get the steels in 2.0 2.3 2.6

All you do is measure the clutch pack and add whatever size you need. The standard ktm is 2.3 so if all our std pack is in decent nick you can just throw it all together and it'll be cool.

I wanted a little bit more slip as it was still moving a lot on the downshifts under braking so dropped to the 2.0 and it's cool.

You can fine tune it further by swapping some of the springs to the std lighter ones if you needed.

It's all on the Sigma site under the race setup section.

bic_bicknell

2012-05-27 09:19:00 UTC

Slip under power is totally gone. Just been out and done a proper test round the countryside and M23 and can't get any other feeling than total power through to the back wheel.

So basically a 1500nm main spring will cope with up to 125 or so HP. It doesn't feel any harder to operate than the old set up to be honest.

The only down side at present is that there is quite a lot of drag, hard to get into neutral and wants to creep forward in first even with the clutch level all the way in. Is this normal when fitting a new set of friction plates? Obviously the clutch pack is slightly wider than the old one and so the same travel when you pull the lever in will not separate the plates as much but I wouldn't it expect to drag like this. Do they need to bed in a bit like brake pads ? The clutch engages very soon as you let out the lever - had to adjust it with the lever span adjust but it's not quite the same thing is it. Maybe I'll bleed the clutch hydraulics because I haven't done this for a while.

Colonel_Klinck

2012-05-27 10:41:00 UTC

Can you email me the contact details and part numbers I need please Bic and I'll get on the case tomorrow.

bic_bicknell

2012-05-27 15:06:00 UTC

drswade

2012-05-27 15:16:00 UTC

Doesn't the choice of spring tension, 1500nm, 1300mn, etc. only effect the pressure of the clutch on deceleration?

The point of the slipper is not to change how the clutch is engaged but how it disengages on deceleration.

I will tell you straight away that the Suter/KTM clutch has infinitely a better feeling clutch than my Yoyo.

TLS_Russ

2012-05-27 15:17:00 UTC

Post missing.

Colonel_Klinck

2012-05-27 15:38:00 UTC

Post missing.

Colonel_Klinck

2012-05-27 15:53:00 UTC

Post missing.

drswade

2012-05-27 18:05:00 UTC

The STD spring worked fine for me but now I wonder if its lack of force causes the pressure plate to wear out prematurely?

Colonel_Klinck

2012-05-27 18:50:00 UTC

Post missing.

drswade

2012-05-27 20:35:00 UTC

If you look at my old link from earlier in the thread you will see I did in fact go through a pressure plate, BIG TIME! Funny thing was I never really noticed it was sipping until it was slipping to almost failure at corner exits, hard on the throttle.

I sold it and a couple of other of my Suters on the forum and I think most of the guys got the new/replacement parts.

I am pretty sure Omky did anyway.

Like I said, I LOVED that clutch!

In hind sight, I would have paid full price for another instead of the Yoyo. That Yoyo was grabby and not exactly smooth.

The slip function was fine but normal use was a bear compared to the Suter/KTM. I went from great launches with the Suter to a grid stall and porpoise wheelies at another grid with the Yoyo.

In that video at Fontana in Jan 2011 you can see the clutch grabbing when I pull out of the garage.

It is what I notice and remember every time I watch it.

SDNerd

2012-05-28 16:37:00 UTC

Post missing.

bic_bicknell

2012-05-28 19:08:00 UTC

Latest story update is interesting. This thread will run and run I think!

Colonel_Klinck

2012-05-28 20:59:00 UTC

omky756

2012-05-28 21:31:00 UTC

Post missing.

bic_bicknell

2012-05-29 04:33:00 UTC

I tested it as much as I could in the few hours I had and couldn't detect any slip under any conditions. After having had a slipping clutch for as long as I have you get very experienced with when it happens and can really hear/feel when it begins to slip. And it doesn't now.

Haven't had a chance to bleed the clutch, need to get some mineral oil, then I'll do it at the weekend. If the drag persists I might swap back to my old set of friction plates just to see if a slightly narrower pack changes anything, (and to see if the slip is cured with the stronger spring).

Not sure what strength Klinky just ordered from Suter, maybe the 1500nm too but if he went for a 1400nm be interesting to see if that works for him.

TLS_Russ

2012-05-29 18:13:00 UTC

Colonel_Klinck

2012-06-01 16:55:00 UTC

Colonel_Klinck

2012-06-18 22:51:00 UTC

New friction plated finally arrived, can anyone tell me the pack thickness of just the 11 friction plates? Also I measured all the steels and 9 of them are between 1.84 -1.88 but 1 of them is 2.14mm thick. This is also the worst marked of the lot. Any ideas why just one is this thick? Was it supposed to be in a particular place in the pack?

Also after a quick go on Ronin's SD I'm going to try the heaviest slipper spring. His Sigma doesn't slip anywhere near as much as mine. Anyone tried the heaviest spring?

omky756

2012-06-18 23:07:00 UTC

Doesn't Suter have an directions sheet of exactly

"How to"

Or

Has anyone put one together.???

I'm thinking it is or should be very straight forward

with exactly where each plate goes and what to look

for..

I'm still waiting to purchase the rest to make my Suter

Slipper and install it..What a lot of pain and suffering

SDNerd

2012-06-19 00:20:00 UTC

Post missing.

omky756

2012-06-19 01:47:00 UTC

Post missing.

Colonel_Klinck

2012-06-19 06:29:00 UTC

I am curious as I bought the EBC friction plate pack. The combined thickness of the 11 plates is 31.16. My old pack is down to 29.88.

This thicker steel is slightly confusing then. There is no mention of it in the instructions for the Sutter or KTM Workshop manual. It looks like the other 9 steels in every way. It's only when I measured each steel that I noticed the different thickness. As I said it's also the steel that has the worst scoring marks on it.

I installed Ronin's SDR pack so I could ride in Scotland at the weekend. His combined pack thickness was 50.13. I will whip out his pack in the next couple of days and see if he has a thicker steel in there.

The reason I ask about the heavier slipper spring is that mine slips on shutting of the throttle at anything over mild acceleration and not just change downs. After briefly riding Ronin's SD it doesn't appear to slip in the same way. I am more worried that this is wearing the steels and friction plates. Does the slip mechanism wear these???

TLS_Russ

2012-06-19 07:31:00 UTC

Sigma Performance Limited

Beadles Yard

Lower Green Road

Rusthall

Tunbridge Wells

Kent

TN3 0NA

Colonel_Klinck

2012-06-19 08:18:00 UTC

Colonel_Klinck

2012-06-19 08:55:00 UTC

SDNerd

2012-06-19 17:11:00 UTC

Post missing.

bic_bicknell

2012-06-19 17:55:00 UTC

My clutch seems sorted now but not like I can get out and try it. Bought some GB engine covers from a member onhere because - to tell the truth, the biggest pain with me sorting this clutch was that my carbon covers are siliconed into place so every time I need to wap off the cover I need to prise them off, clean them up and then silicone them back on. Ever the optimist I do it every time only to have to get them off again. The GB bolt on covers will be a godsend!!!

SDNerd

2012-06-19 18:13:00 UTC

Post missing.

Colonel_Klinck

2012-06-19 19:24:00 UTC

Post missing.

SDNerd

2012-06-19 20:53:00 UTC

Colonel_Klinck

2012-06-19 21:03:00 UTC

Yeah this is the track all the bikes use now. Its good fun and flows quite well, bloody fast in some bits. I'm struggling with a couple of the right hairpins but I always struggle with right hairpins

KronosMotorsports

2013-11-13 20:02:00 UTC

SDNerd

2013-11-13 20:43:00 UTC

Post missing.

KronosMotorsports

2013-11-14 02:04:00 UTC

KronosMotorsports

2013-11-18 18:08:00 UTC

Post missing.

SDNerd

2013-11-18 20:07:00 UTC

Post missing.

BassAgent

2014-03-19 23:00:00 UTC